Can Volume LTL Work for You?

Whether you’re an owner-operator or oversee a fleet, you might have multiple preferences as a carrier, whether they include full capacity, the best lanes, immediate payment, or others.

Good carriers know that flexibility and agility are an important part of success in your business. Sometimes you might need to accept payment after delivery, take less-than-ideal routes, or find your trailer at less than full capacity. But sometimes, you can also turn those obstacles into profits, especially in the case of less-than-truckload or less-than-load (LTL) freight.

One way is to capitalize on volume shipping with volume less-than-truckload jobs. If handled correctly, volume LTL shipping can generate ongoing cash flow in what might otherwise be empty trailer space.

What is volume LTL?

Let’s take a look at the shipper’s side of cargo transportation. Like most carriers, shippers also prefer to send out full loads because of cost and convenience. But sometimes 100% capacity just isn’t going to happen. Maybe the products are too small to fill a trailer. Or maybe inventory is just being rolled out, so it’s a leaner shipment. Whatever the reason, traditional LTL means relatively small amounts of freight.

But freight shipping isn’t an “either-or” business. In between LTL and full capacity is volume less-than-load. Volume LTL helps shippers with more pallets than fit into the standard LTL shipping category, but not enough to guarantee a full truck. This creates a fantastic opportunity for volume LTL carriers and keeps the supply chain moving.

Is volume LTL a replacement for standard LTL freight?

Volume less than truckload and standard LTL both involve a less-than-full trailer. But the freight volume and size requirements are different.

For freight to be designated as volume LTL, it must:

- Weigh more than 5,000 pounds.

- Consist of at least six pallets.

- Measure anywhere from 12 linear feet to 32 linear feet.

From a shipping standpoint, there will always be a need for small transport through the standard LTL, which requires five pallets or fewer. But companies using volume LTL can ship larger product volumes at a lower cost without paying the higher rates of a full truckload.

How does volume LTL work?

Most shippers operate through what’s known as a regional hub-and-spoke model. The spokes are the local drivers who travel around a metropolitan area or specific territory, picking up pallets from different shippers. Those drivers bring the goods to the hub, where they are sorted then consolidated onto destination-based pallets. The shippers then hire truckers to transport those products from the origination point to the end-point hub.

Shippers know that lower capacity is more the rule than the exception with different stages in a route. So to counteract that, they rely on volume LTL carriers. This helps reduce the number of deadhead miles that a truck drives on the road while still generating some extra income.

Moving volume LTL can be less expensive than either a standard LTL or a full truckload. Shippers are paying for a smaller space than the full trailer. From the carrier standpoint, this can mean lower rates. On the positive side, it also helps carriers fill their trailers to capacity, especially when hauling multiple loads.

Volume LTLs vs. partial truckloads

Given that volume LTLs are not full truckloads, aren’t they the same as partial truckloads? Technically, no. Both mean a less-than-full trailer. And both might fit into your trailer to help reach full capacity. But from a shipping point of view, volume LTLs and partial truckloads are not the same things. Partial truckloads are different from volume LTL shipments because:

- They have different sizing specifications than volume LTLs.

- They don’t require a freight class.

- They are established by the market and determined by mileage, specific lane, and required weight and space. Volume LTL rates are based on the carriers’ set, published rates, which are also determined by freight classification.

- They are not crated or carried on pallets.

The upshot? Shippers have different categories for transporting goods in a less-than-full truck. Understanding the difference in terminology can help you stand out to a shipper or broker and make the most of your LTL freight.

Pros and cons of volume LTL

So how does this all help you as the carrier? Like most things in the freight logistics industry, there are benefits, risks, and challenges. Understanding the pros and cons will help you figure out if volume shipping can fit into your business.

Pros

Fills up the empty spaces. One of the main advantages of volume LTL transport is that you can plug some of the harder-to-fill gaps in your trailer. This can help generate more income.

Builds relationships. If you put yourself forward as a volume LTL carrier, you could find yourself in high demand, especially from shippers who don’t have enough inventory for entire trailers. Taking on these jobs also shows that you’re flexible, which is valuable to brokers looking to match loads.

Cons

Lower cash flow. Shippers like volume LTLs because of the cost savings. But for carriers, they usually don’t pay as much as full truckloads.

More paperwork and red tape. Let’s face it. There’s a lot less paperwork involved with one full load than with multiple volume LTLs.

Factors that impact volume LTL rates

Keep these factors in mind when evaluating and setting volume LTL rates.

Freight class. If you’re traveling in the United States, the freight volume and class determine your freight rates. Each product is categorized based on the National Motor Freight Classification System’s density, value, and product specifications.

Destination. Remember that trip from Barstow to Terre Haute? It will be less expensive to haul that same cargo from Barstow to Phoenix or even to Dallas-Fort Worth. The final destination influences cost, which can also impact volume LTL rates.

Dimensions. Your goal as a volume LTL carrier is to optimize space while keeping cargo safe and undamaged. You also need to make sure that freight weight is distributed throughout the truck. For this reason, both size and weight will have a definite impact on what you charge.

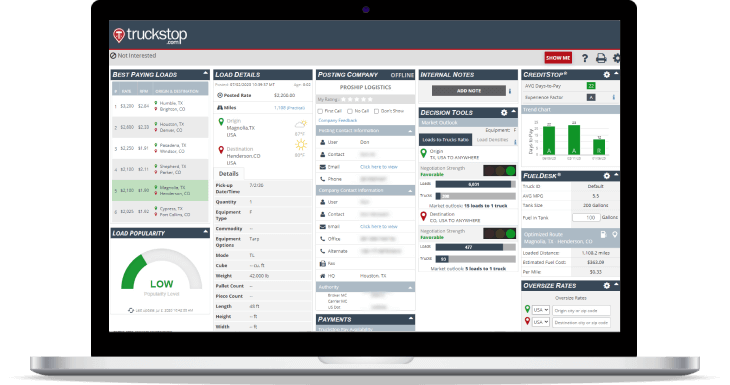

Demand. If a shipper has a lot of product that requires a volume LTL transport, but there aren’t many carriers out there, you can charge higher rates. That’s where using a good load board comes in. Having access to high-quality rate information can help you determine what other lanes are paying and what shippers or brokers are willing to pay for various loads.

Deadhead miles. The spot-based nature of volume LTL pickups and drop-offs also means you might find yourself driving the dreaded deadhead miles (traveling without carrying any loads). Empty space in your truck means no profit. You could mitigate this issue by factoring potential deadhead miles into your quoted rates or by scheduling multiple loads along your route.

Lanes. The lanes you travel will definitely have an impact on what rate you quote to shippers and brokers. For example, the fixed costs of fuel will be the same on a long-distance trip, whether you carry a full truckload or volume LTL. the difference is that you could be paid less to transport the LTL unless you decide to factor in the fuel costs with your rates.

Use a load board to find the best LTL rates.

So, how do you find good volume LTLs? The Truckstop Load Board is a great place to start. Our Less Than Truckload Load Board gives you access to information about vetted and approved brokers and shippers, plus rates, lane availabilities, and real-time updates. Try our free, no-strings demo to see how it works.

Get helpful content delivered to your inbox.

Sign up today.

Find high-quality loads fast, get higher rates on every haul, and access tools that make your job easier at every turn.