Drop and Hook Trucking: How It Works, Pros, Cons and Rates

If you’re in the trucking industry, you might have heard of drop and hook trucking. It’s sometimes thought of as the holy grail for truckers because you don’t have to deal with unloading the trailer. But is drop and hook (also known as drop and pick) really as good as it sounds? Exactly what is drop and hook trucking anyway? Let’s take a closer look at how drop and hook freight actually works.

What is drop and hook trucking?

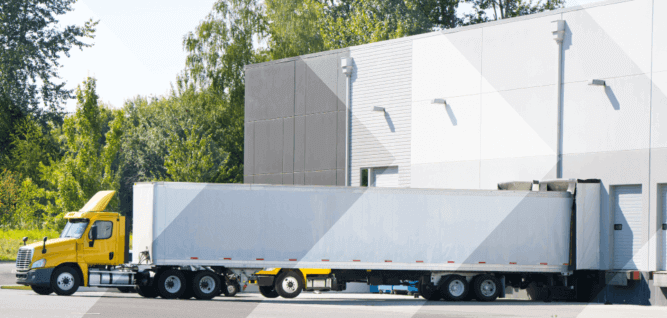

So, what does drop and hook mean in trucking? Simply put, it’s the process of dropping off a full trailer and then hooking your tractor to an already loaded trailer at the same place. The biggest appeal of drop and hook, no-touch freight is that you don’t have to worry about loading and unloading. Rather than spending time dealing with the goods, you drop, hook, and go.

Of course, there can be some challenges. The new trailer might not be sitting at the dock ready to go. It might be hidden behind other trailers or even stored offsite. You might need to get someone to move it to a position where you can grab it, and fully-loaded trailers can sometimes be tough to hook up. Still, many drivers feel that the challenges are worth it, especially if they don’t love the loading and unloading.

Drop and hook vs. live loads

A live load means that the truck driver waits for the trailer to be loaded or unloaded at the dock. If a backhaul is scheduled, the driver has to wait through both the unloading and reloading processes. This can add up to significant time spent at the dock.

In addition, drop and hooks typically don’t need to be scheduled as tightly since they don’t require time at the loading dock or a team ready to load or unload. Live loads must fit within a scheduling window to ensure there is space and labor available.

The flip side is that swapping drop trailers can be a bit of a gamble. If you’re driving equipment you like, you get to use it for live loads. Drop and hook means taking on a trailer that you have no control over. It could be old, weather-beaten, or even in disrepair.

How does drop and hook trucking work?

In ideal conditions, drop and hook trucking works very simply. You drive up and unhook your full trailer. You then hook up the new trailer and go on your way. It’s easy, efficient, and gets you back on the road quickly.

But in the real world, you might run into delays if the new trailer isn’t conveniently positioned, is stored offsite, or is stuck behind other trailers. In those cases, you might need help from a facility worker to get the full new trailer hooked up and ready to go.

Still, average wait times for drop and hook trucking are less than an hour. Wait times can swell to three hours or more for a live load. Many drivers and carriers like the convenience of drop and hook trucking. It can also be better for some shippers because they can pre-load trailers when they want instead of sticking to a tight schedule of live loads.

Who uses drop and hook trucking services?

Understanding which facilities use drop and hook services can help you decide whether these loads are right for you. Shippers choose these services for many reasons. Here are some of the most common:

- Loose, floor-loaded cartons. Loose items can take longer to load and unload than a container does. It’s easier for some shippers to pre-load this freight into a trailer rather than taking time for a live load.

- Warehouse backups. It can be tough to schedule live load appointments when the warehouse is backed up. Drop and hook may be the best solution when there’s too many goods or not enough staff.

- Enough trailers and space to park them. No matter how backed up a warehouse is, drop and hook isn’t possible unless the facility has multiple trailers and enough room for them.

- Time constraints. No matter what the reason, time-consuming loads and unloads have a domino effect. Trucks get backed up, delivery dates get delayed, and transportation costs may rise.

- High volume shipping. There are only so many hours in the day, and only so many live load appointments can fit. Those with consistently high shipping volumes often find that drop and hook trucking services help them stay on track.

Benefits of drop and hook trucking

- No-touch freight. Some facilities require truck drivers to help load and unload trucks. Others have a dedicated team for that. Either way, drivers need to hang around the dock until the job is done. Drop and hook means drivers avoid the load and unload process altogether.

- Faster deliveries. Skipping load and unload means less time at the dock and more time on the road. This can be a huge time advantage, and more mileage means more pay.

- Easier scheduling. Drop and hook makes scheduling easier for drivers, carriers, and shippers. Rather than having to deliver in a tight window, shippers can pre-load at their convenience, and drivers can pick up and drop off at theirs.

- Lower shipping costs. Drop and hook shipping may be less expensive than managing backups for shippers with warehouse issues or who deal in high volumes.

Challenges of drop and hook trucking

Consider these factors when deciding whether to offer the service.

- Stuck trailers. Depending on the facility, the new trailer might not be readily accessible. Whether stuck behind other trailers or stored offsite, a trailer that isn’t ready to go can spell delays.

- Trailer quality. Drop and hook drivers trade their own trailer for an unfamiliar one. If you like your current equipment, you might not want to take a gamble that the next trailer may or may not be in good shape.

- Overweight trailers. Drivers are responsible for ensuring that the equipment they use complies with all guidelines, including weight restrictions. If the shipper overloads the trailer, you may need to return to the facility to offload some items.

- Hookup issues. A fully loaded trailer can be heavy and difficult to hook up. If you can’t maneuver the trailer alone, you’ll need to find a facility worker to help, which eats up time.

FAQs

Use a load board to find the best drop and hook rates.

Are you ready to book quality drop and hook loads? The Truckstop Carrier Load Board offers a variety of tools to help you choose the right loads and negotiate top rates with trusted brokers. Find the plan that’s best for you.

Find out how our platform gives you the visibility you need to get more done.

Get helpful content delivered to your inbox.

Schedule a demo.

Find out how our platform gives you the visibility you need to get more done.